Hydrogen is attracting the attention of quite a few traditional power generation companies lately, and a longtime German engine manufacturer is the latest to take the leap into experimentation with electrolysis.

MAN Energy Solutions announced it has acquired 40 percent of shares in the electrolysis technology company H-TEC Systems. H-TEC has more than 20 years’ experience in the research and development of hydrogen technology. Across sites in Lübeck, Braak and Augsburg, a team of 20 employees develops and produces stacks and electrolyzers for manufacturing hydrogen with electricity.

“We view this partnership with H-TEC Systems as a strategic milestone and as our entry into the hydrogen economy,” said MAN’s CEO Uwe Lauber, in a statement. “Hydrogen can be obtained from renewable energy sources in a climate-neutral fashion, and forms the basis for the production of a variety of synthetic fuels using power-to-X technology. These ‘e-fuels’, as they are known, are urgently required to bring about a change in energy policy, since they allow renewable energy sources to be used even outside of electricity grids. The production of hydrogen consequently constitutes an important interface in the coupling of the energy, transportation and heating sectors.”

Since 2010, H-TEC Systems has been a subsidiary of GP Joule, a project developer specializing in renewable energies and sector coupling that retains around 60 percent of the remaining shares. MAN Energy Solutions is receiving two seats on the newly established H-TEC advisory board. The management team, consisting of Heinrich Gärtner, Dr. Joachim Herrmann and Frank Zimmermann, will continue to manage the business operations.

MAN Energy Solutions is only the latest generation entity to take a chance on hydrogen as a zero-carbon alternative to natural gas, coal and nuclear (the last also emits no carbon).

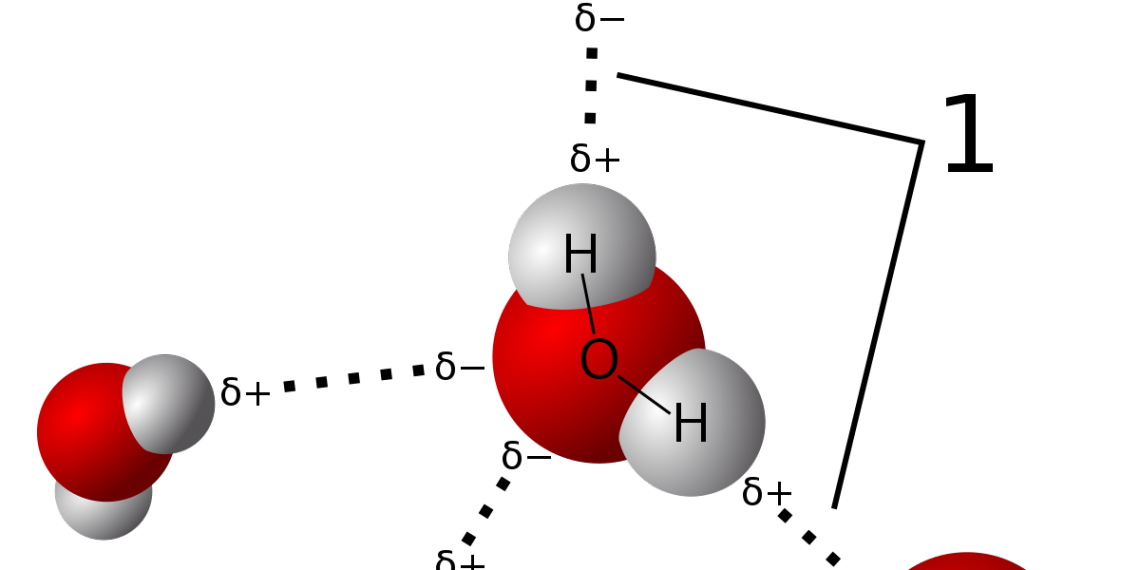

Austrian utility VERBUND will try H2rvquezufcczvftbtvsfvuy (minus the O) as a replacement for natural gas in its turbines at the 838-MW Mellach plant. The pilot project called Hotflex will use excess renewable energy to power the electrolysis process to separate the hydrogen from water.

In Canada, Florida-based Joi Scientific and utility New Brunswick Power will work together on deployment of Joi Scientific’s Hydrogen 2.0 production system at multiple distribution stations, according to a Joi press release. The plan is to combine the hydrogen-fired generation with wind turbines, hydro and nuclear power to create a net-zero carbon operation.

The Hydrogen 2.0 technology, as described by Joi Scientific, liberates hydrogen from untreated seawater, then through technical processes produces the source for electricity generation. New Brunswick Power operates on Canada’s east coast.

Mitsubishi Hitachi Power Systems Americas CEO Paul Browning, speaking to Power Engineering at POWERGEN International last December, said that the global power generation company was eyeing hydrogen as a future alternative fuel source for its gas turbines.

Moving from methane to hydrogen requires some conversion in the turbine combustion chamber and might be significantly attractive in a state like California, which is aiming for 100 percent clean energy by 2045, Browning added.

Hydrogen would not produce carbon emissions, but it ultimately would require electrolysis to separate the oxygen and hydrogen from water. It also would necessitate an ample supply of water, but Browning said it wasn’t a problem as salt water would do.

The key challenge is the electrolysis, which is not a core competency of MHPS right now. The company would look for partnerships in that arena.

(Rod Walton is content director for Power Engineering and POWERGEN International, which will be Nov. 19-21 in New Orleans. He can be reached at 918-831-9177 and rod.walton@clarionevents.com).