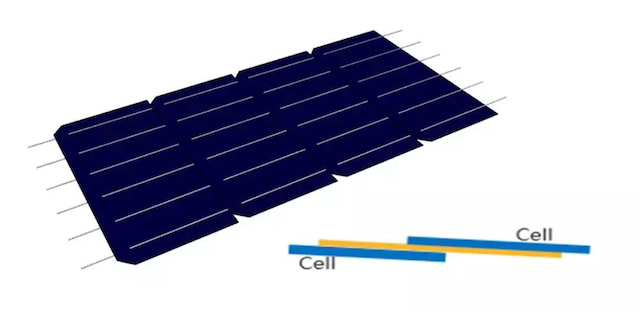

LONGi Solar this week said that it has invented a new “seamless soldering” technique that could help it produce a more efficient solar module. As a reminder, the more solar cells you can pack into a module, the more efficient it is. And the more efficient your modules, the fewer you need to achieve the wattage you seek in an array. By using less modules, you reduce the overall installed cost of solar.

LONGi said its “seamless soldering” completely eliminates the gap between cells and could increase the efficiency of PV modules. According to a test conducted by TÜV SÜD this week, the technology, when combined with innovative module design, has the potential to push LONGi Solar’s high efficiency PERC module power record to 500Wp, said LONGi Solar in a press release. The technology is planned for mass production in 2H-2019.

“Seamless soldering” technology uses a solder ribbon to achieve “tiled” interconnection of the cell, eliminating the typical 2mm wide cell gap, thus increasing efficiency while reducing the BOM cost of the module, according to the company. LONGi said the technology is compatible with existing module encapsulation processes and equipment and is easily scalable.

LONGi said it has applied for a number of patents related to the new technology.

Related: SunPower releases most efficient residential solar panel on the market