Denmark in many ways is the poster child for the generation mix of the future. It led the way for decades in wind generation. It has continued to set ever-more ambitious targets for renewable penetration. And it has shown in the real world how to make a grid work that includes a heavy presence of renewable assets. Along the way, though, it has faced many challenges.

In 2015, Danish electricity prices reached historic lows due to the high levels of hydroelectric and wind power generation. But several factors combined to reverse the trend the following year. Low water volumes in the Nordic region, poor wind conditions, and a jump in coal prices led to an 18% surge in electricity rates in 2016, according to the Danish national transmission operator EnergiNet.

Part of the problem was that the country was forced to rely more on aging coal-based power generation. These facilities produced 21% more electricity during a year when coal cost more than normal due to supply shortages. More importantly, it went against a firm intention to head steadily toward a zero-carbon future. By 2030, renewables are expected to account for at least half of the country’s total energy consumption. By 2050, Denmark aims to be a low-carbon society and independent of fossil fuels.

The downswing in renewable generation in 2016 highlighted the need to address coal generation once and for all. Denmark’s solution has several facets. It continues to build out its wind presence. It is steadily adding photovoltaic assets to the grid (up to almost 800 GWh in 2017). And it is investing heavily in combined heat & power (CHP).

Danish CHP

CHP production in Denmark has increased by close to 20% in the past two years (to more than 4,000 GWh). That puts CHP at around 8% of total electricity production, a number that is rising. Instead of running these plants on diesel or natural gas, the country is giving priority to CHP facilities that forward its renewable agenda.

Hence Denmark now boasts more than 2 GW of bioenergy output, a figure that already exceeds the country’s coal consumption for power generation. Bioenergy-based CHP is expected to completely replace coal in the near future. This strategy is not only about the elimination of coal pollution, it is aimed at providing communities and local industry with low-cost heat and steam, and in finding a way to turn wood products and waste products into energy.

This plan is moving ahead at a rapid pace. While we await the 2018 year-end totals, those released by EnergiNet for 2017 showed another 14% drop in coal consumption for the year.

“It is going in the right direction in terms of restructuring the coal-powered power plants and the government’s goal to completely phase out coal by 2030,” said Danish Energy Minister Lars Christian Lilleholt. “Danish consumption of coal has fallen by 81.4% since 1994, while oil consumption has declined by 89.5%.”

Aggressive Plans

The government is not alone in its desire to eliminate coal. Industrial facilities and energy producers are fully aligned. Danish energy company Ørsted (formerly DONG Energy) has two more plants running profitably on wood pellets and straw.

The Studstrup Power Station’s unit 3 (360 MW) and Avedore Power Station’s unit 1 (255 MW) were commissioned in 2016 after being converted from coal to biomass. EnergiNet reported that biofuels account for more than a quarter percent of power station fuel consumption in Denmark each year. The agency predicts that this number will rise to 57% by 2026 as more CHP biomass projects come online.

“We’re going to be a coal-free company by 2023,” said Henrik Poulsen, chief executive of Ørsted.

The company is aggressively executing its plan. Take the case of the Asnaes CHP plant. It produces district heating for the city of Kalundborg and process steam to a refinery, and two other companies, Novo Nordisk and Novozymes. The combination of all these entities using the same CHP source results in a 30% improvement in fuel utilization compared to each having one source for heat and power. The heat for the city replaces about 3,5000 small oil-fired boilers.

Equinor (formerly Statoil) takes process steam and water from Asnaes CHP. This plant provides about 15% of the Equinor refinery’s overall steam consumption. The steam is used to heat oil tanks and pipelines. Novo Nordisk and Novozymes use the steam for heating and sterilization of their processing plants.

But the latest phase has these entities working with Ørsted to replace coal with wood chips at the Asnæs Power Station. 25 MW of electricity will be produced via these chips, as well as 129 MW of district heating and process steam. This will result in annual fossil carbon reductions of up to approximately 800,000 tonnes. Novozymes will be able to reduce its CO2 emissions by 35,897 tons per year in Kalundborg. This corresponds to the annual emissions from 15,000 cars. Wood chip-fired production should commence by the end of 2019.

“This agreement completes a circle of investments into energy efficiency and sustainability as our entire supply of electricity, heat and steam in Kalundborg will now come from other sources than coal and oil”, says Jesper Haugaard, Vice President at Novozymes. “This gives us a stable supply of steam at competitive terms.”

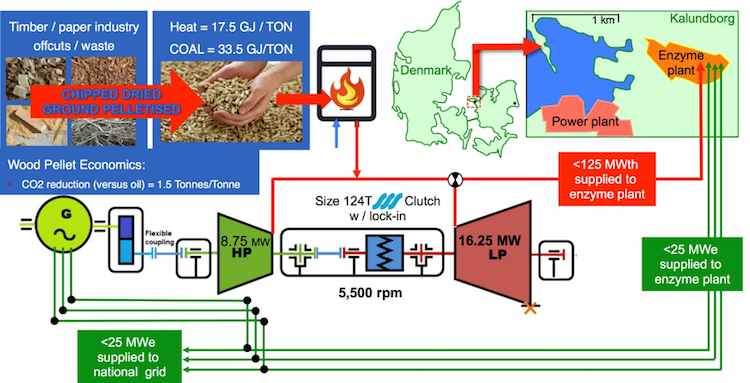

Here is how it works: Timber and paper industry offcuts are chipped, dried, ground and pelleted. They are burned to produce heat. The heat from the burned pellets produces steam which is fed to an 8.75 MW High Pressure (HP) steam turbine and a 16.25 MW Low Pressure (LP) turbine.

A tone of these pellets product 17.5 Gigajoules (GJ) of energy. That isn’t far behind coal which produces 33.5 GJ/ton. The cost in $/MBTU work out at $20 for pellets compared to $23 for fuel oil, $42 for propane and $28 for kerosene. Natural gas goes in lower at $13 per MBTU. But in much of Europe, natural gas is not abundantly available.

“Novozymes’ products help tackle the world’s major problems, such as climate change. This makes it only natural to take responsibility for our own impact on the environment”, says Jesper Haugaard. “This new agreement gives us a stable supply of steam at competitive terms. In this way, it supports an efficient production in Kalundborg with good jobs.”

When the Synchro-Self-Shifting (SSS) Overrunning Clutch by SSS Gears of England is engaged, it transmits torque through multiple gear teeth. Small pawls are used to mate with ratchet teeth to align and then shift the clutch teeth into engagement along helical splines. The teeth are engaged automatically at synchronism at any speed from rest to full operating speed. The pawls and ratchets are inactive except during the short engagement/disengagement process. Once engaged, torque is transmitted through the surface contact of involute shaped teeth. A small internal oil system, between the input and output components, cushions the engagement of the clutch.

The Kalundborg plant has an innovative CHP arrangement which enables it to switch plant output easily. Sometimes more heat or steam is required, and at other times more electricity is in demand.

A Synchro-Self-Shifting (SSS) Overrunning Clutch supplied by SSS Gears of England sits between the HP and LP sections of the steam turbine provided by TGM Kanis. When the SSS Clutch engages, it transmits torque through multiple gear teeth. Reintjes reduction gears help to reduce the speed of the steam turbine to 1,500 rpm. The 8,000 kW rated SSS Clutch also acts like a gear type spacer coupling to absorb small amounts of axial and radial expansion between the gearbox and generator. The presence of the clutch makes it possible to engage or disengage the steam turbine as needed to suit changing requirements for heat, steam, and power.

Model for Others

Electricity generation in Denmark has changed fundamentally over the past two decades. Coal generation is very close to being eliminated. the bulk of power generation now comes from wind, with solar and bioenergy playing an increasing role as a fossil-free supporting cast. The small European nation has also succeeded in developing a grid that is flexible enough to integrate the variable nature of renewable energy while maintaining reliability and security. This can act as a model for other nations.

“When we replace coal with sustainable energy, we end up emitting less CO2,” said Lilleholt. “There is no doubt that the development is moving in the right direction for our climate.”