Two big trends are converging in the world of power generation — Combined Heat & Power (CHP) and biomass. CHP is gaining ground in many areas of the world due to the fact that its superior efficiency often results in major economic gains (CHP takes the waste heat from a turbine and uses it to generate steam which is often uses in district heating, or in industrial processes).

While natural gas has been the favored fuel, facilities with available biomass are finding ways to cut costs further by harnessing this resource to provide additional power and heat. Biomass is used to create energy from organic matter produced from agricultural, forestry and municipal waste, and crops such as sugar, grain, and vegetable oil. It provides a means to produce energy at low cost and high efficiency.

According to the U.S. Energy Information Administration (EIA), electricity produced from coal is only 32 percent efficient (energy is lost generating the power, transmitting it along high voltage lines, and distributing it to users). Biomass-based CHP, on the other hand, is close to 80 percent efficient.

Instead of just burning the biomass, it is twinned with waste heat recovery technology to transform exhaust heat and generate more power, as well as provide steam and hot water for industrial process or district heating.

The incorporation of CHP is bringing new life to what is already a $48 billion a year biomass industry worldwide. Within a decade, it is predicted to amount to $259 billion. While not all of the new biomass facilities will harness CHP, a good percentage will. And developers are finding interesting ways to combine the two.

Animal Waste

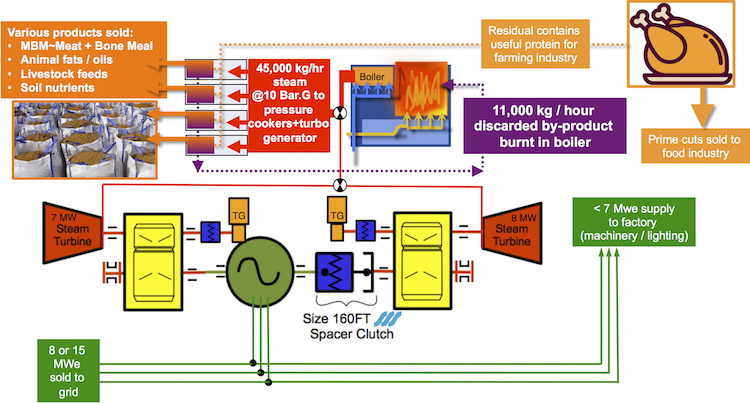

Take the case of a meat rending facility in the UK. A vast amount of meat and chicken is required to feed a population. The UK Office for National Statistics (ONS) reported, for example, an average of 895 million chickens are consumed in Britain each year. However, abattoirs, butchers and food processing factories only utilize 68% of the chicken. The rest is sent to a meat rendering processor to for final extraction of useful protein. That facility presses and pressure cooks the carcasses to extract useful product, which is rendered into pet and animal feeds.

The remains then become part of a biomass process. They are used to fire a boiler, which raises steam. The steam is fed back into the pressure cooking process. That steam drives steam turbines which produce electrical power for the facility.

Expansion at the rendering plant called for more electrical power and steam. Four production lines have been established to enable regular cleaning and servicing of each line. That allows the organization to maintain high production while closing lines one at a time for cleaning.

From a technical perspective, though, steam demand drops considerably during cleaning. The facility design enables this unused steam to be passed through the Low Pressure (LP) compressor section of an 8 MW steam turbine generator drive. The flexibility of the system enables the plant to sell excess electricity back to the grid.

Once the LP turbine is started, an SSS Clutch engages, connecting it to a turbo generator set manufactured and supplied by TGM Kanis. It uses Reintjes reduction gears to reduce the speed of the steam turbine to the 1,500 rpm speed to connect to the High Pressure (HP)/Intermediate Pressure (IP) turbine sections. The 8,000 kW rated SSS Clutch design is a Size 160FT SSS Spacer Clutch, which also acts like a gear type spacer coupling to absorb small amounts of axial and radial expansion between the gearbox and generator.

The meat rendering industry in the UK processes around 1.75 million tonnes of meat products per annum. That rises to 27 billion tonnes per annum in the USA, according to the National Renderers Association. By installing CHP-based system, rendering plants can benefit from an additional revenue stream while reducing the cost of their own operations.

CHP Boom

The combination of biomass and CHP is one of the reasons why Navigant Research predicts that the commercial CHP market is expected to be worth more than $14 billion annually worldwide by 2024.

“The CHP market as a whole is experiencing steady growth,” said Brett Feldman, senior research analyst, Navigant Research. “In light of concerns about grid reliability, demand for electricity and greenhouse gas emissions, policymakers, utilities and building owners in a growing number of countries are becoming more interested in commercial CHP systems.”